Audis UFO Inboard brakes

- Nils Willner

- Sep 11, 2022

- 4 min read

If you have been working on cars already in the 90s and 2000s you may have seen Audis UFO brakes. They are mostly forgotten and became a curiosity in the car world like Mercedes Monowipers, trafficators/semaphore signals or the high beam foot switches.

Audi has tried to push the limits with this type of overly complicated disc brake assembly which was found on the brands top of the line models the Audi V8, its predecessor the 200 (C3) and the first S4 model (Ur-S4 C4). The UFO brake could only be found on the front wheels while the rear wheels used a traditional brake disc assembly. This is an example of German over-engineering and making something more complicated than it has to be.

Why they Exist

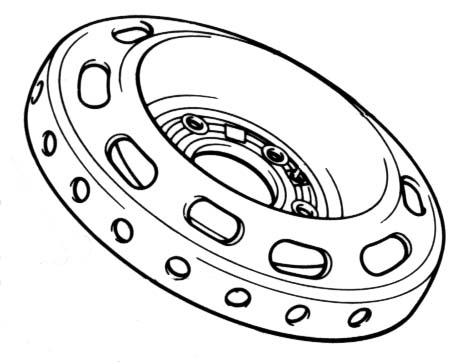

Technically, these “UFO brakes” are called internal calliper brakes or sometimes also referred to as inboard brakes. Audi's luxury sedans became ever more powerful and faster with the V8 being the first car to use a V8 engine. The German engineers didn't want to increase the at the time large 15" wheel but still wanted to fit bigger brakes, callipers and discs. When Audi developed the V8 in the late 80s, 17″ wheels were the biggest wheels you could find on a production sports car but they were quite rare and not the standard like today. Due to the limitation of the wheel size, brake rotors couldn’t get bigger than 12″. The 1987 Porsche 911 came with 11.1″ brake rotors which today are as big as the rotor size of a modern Fiat 500. Audi wasn’t willing yet to mount 17″ wheels to make room for bigger rotors. Therefore, the UFO brake system was designed and built by brake OEM manufacturer ATE in collaboration with Audi. Eventually, after a lot of research, development and testing they managed to squeeze a 12.1" brake rotor in a 15" wheel with less than 3" of space between rim and rotor. The biggest rotors found today on a production car are the Lamborghini Urus (also developed by VAG) massive 17" rotors which can only be fitted in its massive 21" wheels.

How they work

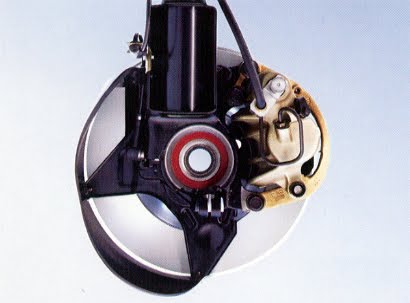

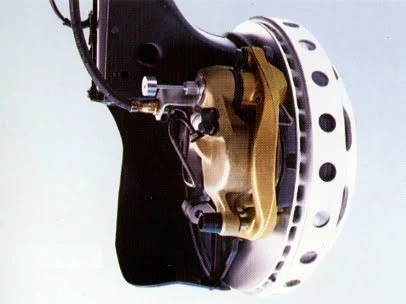

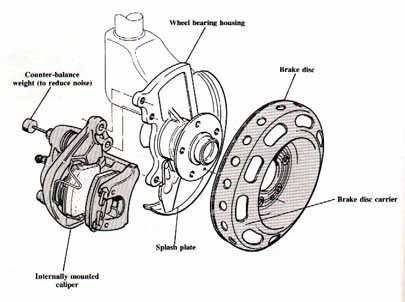

By mounting the calliper inside of the rotor, the disc itself could be larger because there didn't need to be a gap between the disc and the inside of the wheel rim to hold space for the calliper. While the surface area of the rotor only increases marginally, the swept area of the pads increases with diameter.

The rotor is mounted on the hub by a drum casting which allows the calliper to grab the rotor’s surface from the inside. This system makes it mechanically easier for the brakes to slow down the wheels and also helps with dissipating the heat more quickly. The big drum which wraps around the calliper allowed the brakes to have a larger heat sink. It extends the contact patch of the inside wheel area with extra material that can absorb heat.

The Problem

The biggest issue for Audi was the cost to produce the complex saucer discs. Standard brake rotors often come in one size which fits multiple models across several makes. With a completely different brake design, it wasn't possible to use the same tooling systems and take advantage of the economics of scale. Since it cost Audi a pretty penny to produce these discs they had to forward parts costs to customers. While a standard brake rotor cost around $100 at the dealership, these were a whopping $550.

Additionally, the teething problems with the UFO brakes started to become clear only when the cars were already manufactured. The UFO rotors were effective in theory and during testing but didn’t hold up well in the real world because they were very susceptible to warping. They would easily overheat and warp particularly in stop-and-go traffic when the rotors didn't receive enough cooling air stream. A brief stop and holding the brakes at a traffic light caused the rotor to develop a hot spot because half of the rotor would cool faster than the other half. The contracting metal at the cooler spots would bend the disc and create an uneven braking surface leading to vibration. This was very common and it would have required convincing the owners to change their driving habits. These brakes were also very hard to work on which didn't go down well with Audi mechanics and the car owners paying the bills for extra repairs. Eventually, Audi came around and started recommending aftermarket replacement brake systems which were conventional Girling dual-piston callipers and traditional rotors. Unfortunately, this required completely changing the front hub assembly due to different calliper mounting points. Most cars equipped with the UFO brake systems have been converted, but the originals are still out there.

After the production was ended and the stock was sold out, cars could be officially converted to standard VAG rotors. Today, old UFO discs are hard to find for collectors and purists who want to keep their Audi as original as possible and preserve this piece of engineering history.

In the end, Audi proved to the world that they could fit a 12″ brake rotor behind a 15″ wheel. The Audi V8 Quattro was able to stop from 60 mph or 96 km/h at 120 feet or 36 meters which was unheard of and only the best performance cars could achieve this. The UFO brakes might not have been successful but they surely provided insights and advances in brake technology. By 1995 brake and tyre technology had advanced to make the UFOs obsolete. Larger wheels and lower tyre profiles became more widespread and acceptable which allowed enough space for traditional brake systems and lead Audi to abandon this system.

The cars that came with these rotors are on the brink of becoming collectibles and good examples with low mileage are increasingly hard to find especially with the original UFO rotors.

Not just Audi was experimenting with inboard brakes. Honda also did something similar on some of their motorbikes back in the 80s. The 1989 Honda VTR 250 and the 1982 Honda CBX550 featured inboard brakes which worked similar to Audi's UFO system.

If you want to learn more about classic car mechanics, consider buying the book: "The Ultimate Classic Car Guide - How to Buy, Maintain and Repair Classic Cars".

Nils Willner

Nils is a Swiss-German engineer who is obsessed with old cars and engines. He is the author of "The Ultimate Classic Car Guide - How to Buy, Maintain & Repair Classic Cars" and the founder of EVC. His passion has always been with old cars and everything with wheels and engines.

Des freins a disque avec étriers a l' intérieur étaient utilisés sur les Porsche 804 de Grand Prix en 1962.

Thanks for your comment and the photo! I remember the Buell motorcycles having this special brake arrangement. Thanks for the reminder.

Great write up! I had no idea these existed on cars at all. Buell motorcycles still use this concept on their front wheels with what they call a “Perimeter disk” setup.